In the rugged world of heavy machinery, where steel giants shape our infrastructure and fuel our industries, a quiet revolution is underway. It's not about bigger engines or stronger materials, but about the invisible streams of data that are transforming how these titans are operated, maintained, and managed. Welcome to the age of telematics in heavy machinery – a paradigm shift that's redefining efficiency, safety, and sustainability across industries.

- Heavy machinery faces massive challenges, with mining projects exceeding budgets by 43% and construction losing $984 million annually to equipment failures.

- Telematics enables real-time monitoring, predictive maintenance, safety enhancements, and emissions management in heavy machinery.

- Navixy integrates a wide array of data sources to provide comprehensive equipment monitoring and operational insights across industries.

The heavy machinery landscape: A sector ripe for innovation

The global heavy machinery market, valued at $177.58 billion in 2020, is projected to reach $231.99 billion by 2025, growing at a CAGR of 5.4% (MarketsandMarkets, 2021). This growth is driven by urbanization, infrastructure development, and technological advancements. However, the industry faces significant challenges:

- Operational inefficiencies

A study by McKinsey & Company found that large mining projects routinely exceed their budgets by 43% and their schedules by 63%, often due to equipment-related issues (Resolving the crisis in mining productivity, 2017). - Rising maintenance costs

The U.S. construction industry alone loses an estimated $984 million annually due to unexpected equipment failures (Association of Equipment Management Professionals, 2019). - Safety concerns

The heavy machinery sector accounts for a disproportionate number of workplace injuries and fatalities. In the U.S., construction equipment-related incidents result in about 400 fatalities annually (Occupational Safety and Health Administration, 2020). - Environmental pressures

With heavy machinery contributing significantly to industrial emissions, the sector faces increasing scrutiny. The European Union's Stage V emissions standards, for instance, mandate a 96% reduction in particulate matter emissions from non-road mobile machinery (European Commission, 2016).

These challenges underscore a pressing need for innovative solutions that can enhance operational visibility, predict maintenance needs, improve safety, and support sustainability efforts. In response to these industry-wide demands, telematics has emerged as a transformative technology, offering comprehensive approaches to address these complex issues.

Telematics – the nervous system of modern heavy machinery

Telematics, at its core, is about the transmission of computerized information over long distances. In the context of heavy machinery, it involves the collection, transmission, and analysis of data from equipment in real-time. This technology is rapidly becoming indispensable in the industry, with the global construction equipment telematics market expected to grow from $676.2 million in 2019 to $1,498.5 million by 2024, at a CAGR of 17.2%.

The adoption of telematics in heavy machinery is not just a trend; it's a fundamental shift in how these assets are managed. A recent survey by the Association of Equipment Management Professionals (AEMP) found that over 80% of construction companies using telematics reported significant improvements in operational efficiency, with an average of 15% reduction in fuel costs and a 20% increase in overall productivity (AEMP Telematics Usage Report, 2020).

How Navixy pioneering advanced telematics for heavy machinery

In this landscape of technological transformation, Navixy emerges as a pivotal player. As an all-in-one GPS fleet and asset tracking platform, Navixy is tailored to meet the unique demands of heavy machinery management. Its comprehensive approach addresses the multifaceted challenges faced by the industry, offering a suite of features that translate raw data into actionable insights.

Navixy's 360° equipment vigilance

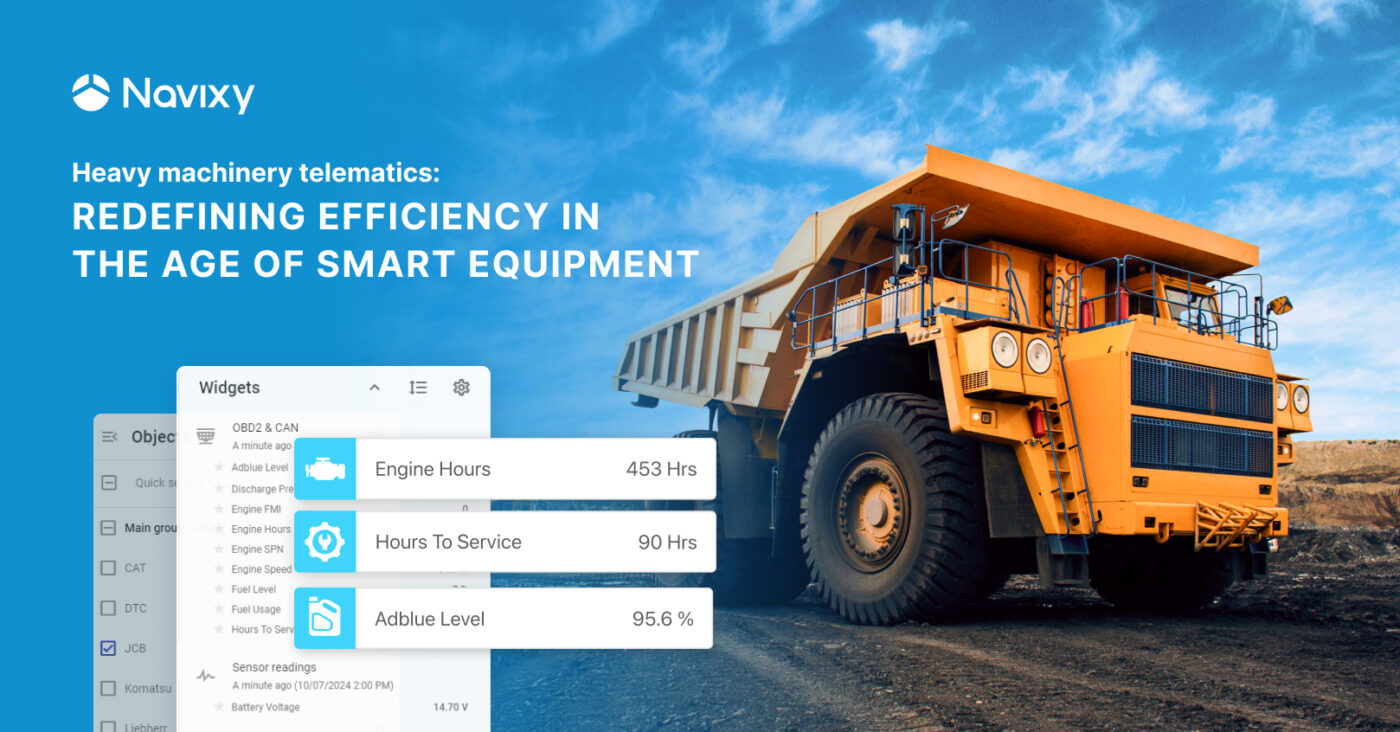

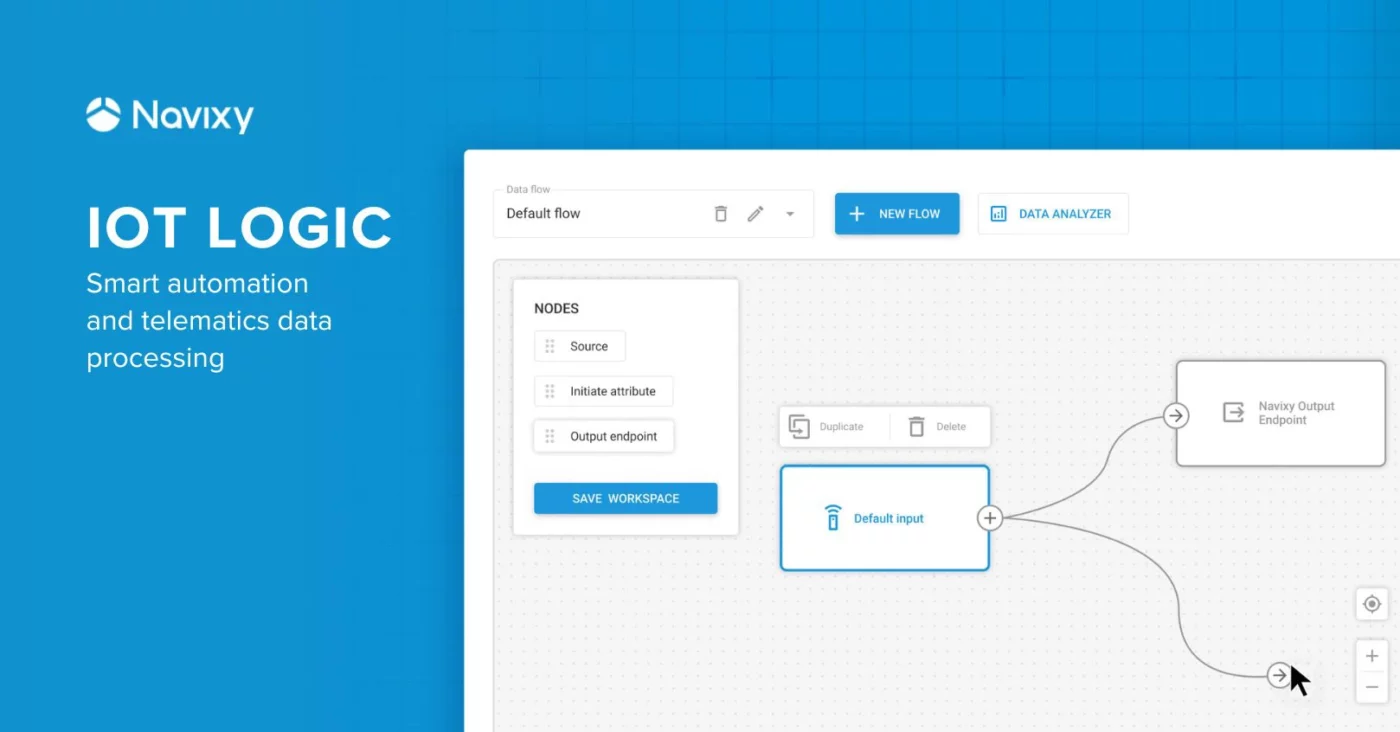

At the heart of Navixy's offering is its ability to provide a holistic view of equipment performance. By integrating with GPS, OBD2/CAN and Video systems, Navixy captures a wealth of real-time data that is crucial for proactive equipment management.

Consider the tracking of engine hours — a seemingly simple metric with profound implications. When a JCB excavator logs 453 hours of operation, it's not just a number. It's a critical indicator for maintenance scheduling, a data point that can prevent unexpected breakdowns and extend the machine's lifespan.

Research by the Construction Industry Institute suggests that implementing a proactive maintenance program based on such data can reduce maintenance costs by up to 25% while increasing equipment availability by 35% (Construction Industry Institute, 2018).

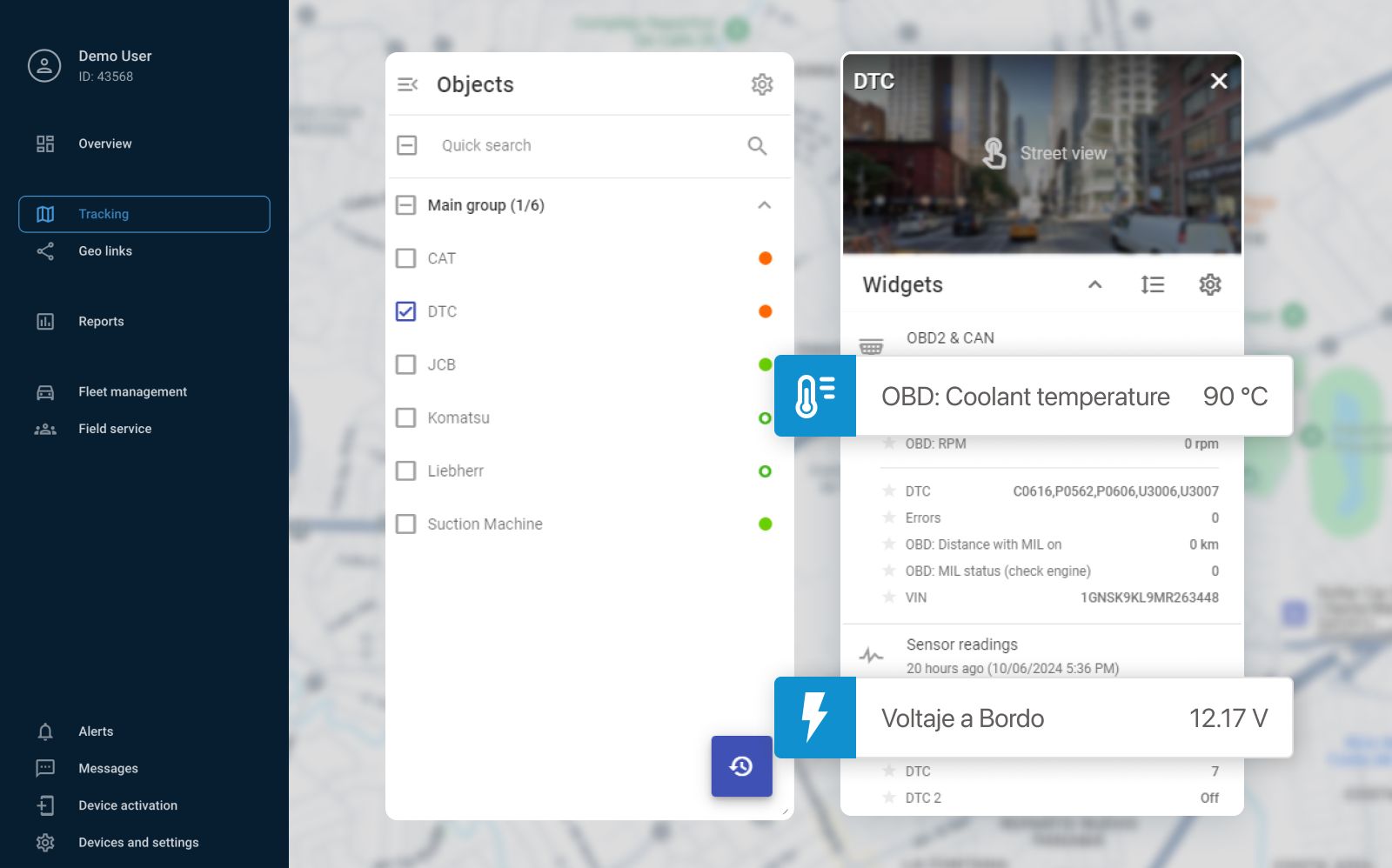

But Navixy's monitoring capabilities extend far beyond engine hours. The platform tracks critical vehicle parameters like coolant temperature and battery voltage — vital signs that can predict and prevent catastrophic failures. When a machine reports a coolant temperature of 90°C and a battery voltage of 12.17V, it's not just information; it's assurance. These readings, within normal operational parameters, provide operators and managers with the confidence that their equipment is functioning optimally.

Navixy's prowess in comprehensive monitoring is further enhanced by its unparalleled flexibility in device compatibility and connectivity options. Recognizing the unique challenges faced by industries operating in remote areas, such as mining or road construction, Navixy has forged partnerships with leading connectivity providers to offer robust solutions.

The platform seamlessly integrates with hybrid cellular multi-carrier systems, satellite communications, and Low Power Wide Area Networks (LPWAN), ensuring that vital data flows uninterrupted from even the most isolated worksites. This adaptability is complemented by Navixy's device-agnostic approach. By collaborating with the world's foremost telematics device manufacturers, Navixy empowers businesses to select specialized equipment tailored to their specific needs, regardless of geographical constraints.

Predicting breakdowns before they happen

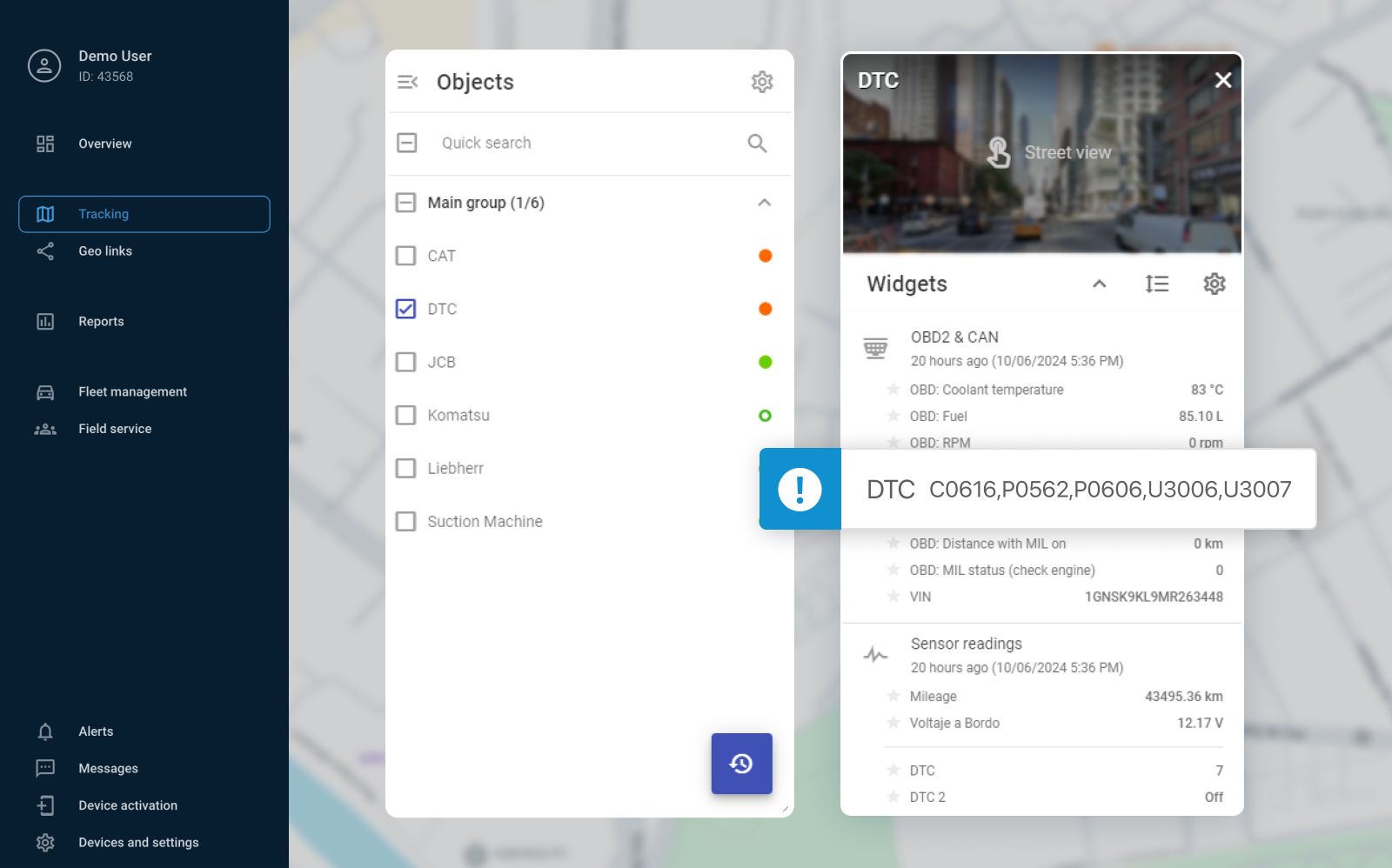

In the realm of heavy machinery, where a single hour of downtime can cost thousands, early fault detection is invaluable. Navixy's ability to capture and interpret Diagnostic Trouble Codes (DTCs) in real-time serves as an early warning system, allowing technicians to address issues before they escalate into major problems.

The impact of such predictive maintenance capabilities is significant. A report by Deloitte found that predictive maintenance can reduce the costs of maintenance by 5-10% while increasing equipment uptime by 10-20% (Industry 4.0 and the digital twin, Deloitte University Press, 2017). When Navixy reports multiple fault codes, it's not just flagging issues — it's potentially saving hundreds of thousands in repair costs and preventing project delays.

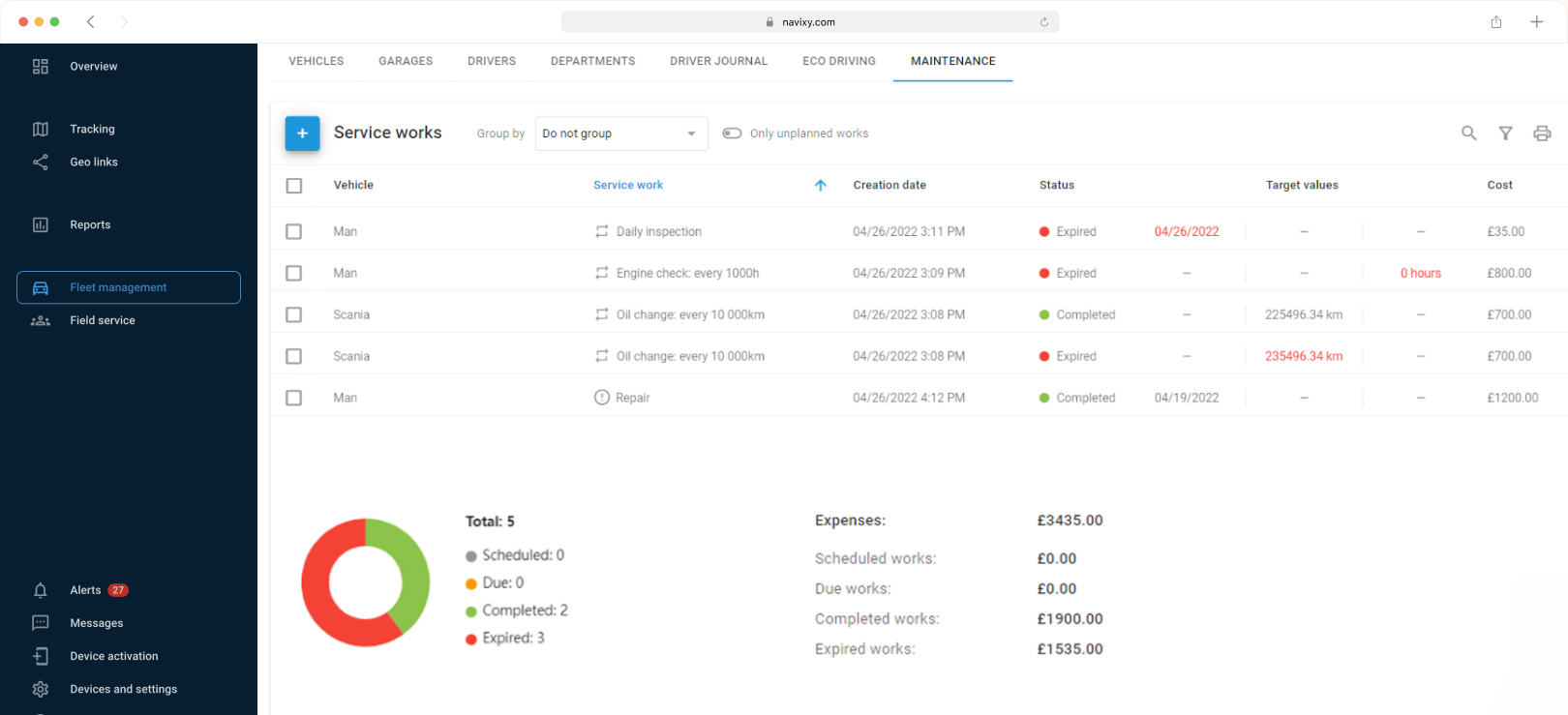

Navixy’s fleet maintenance module complements its diagnostic capabilities by supporting both planned and unplanned maintenance. This module acts as a central hub, integrating diagnostic data for a holistic maintenance experience. Managers can schedule routine services based on engine hours, mileage, or dates, with reminders to ensure preventive maintenance isn’t missed. Notably, companies implementing predictive maintenance strategies, like those enabled by Navixy, have seen 20% higher Overall Equipment Effectiveness (OEE) than those relying solely on reactive maintenance (Aberdeen Group, 2017).

High-tech safety net

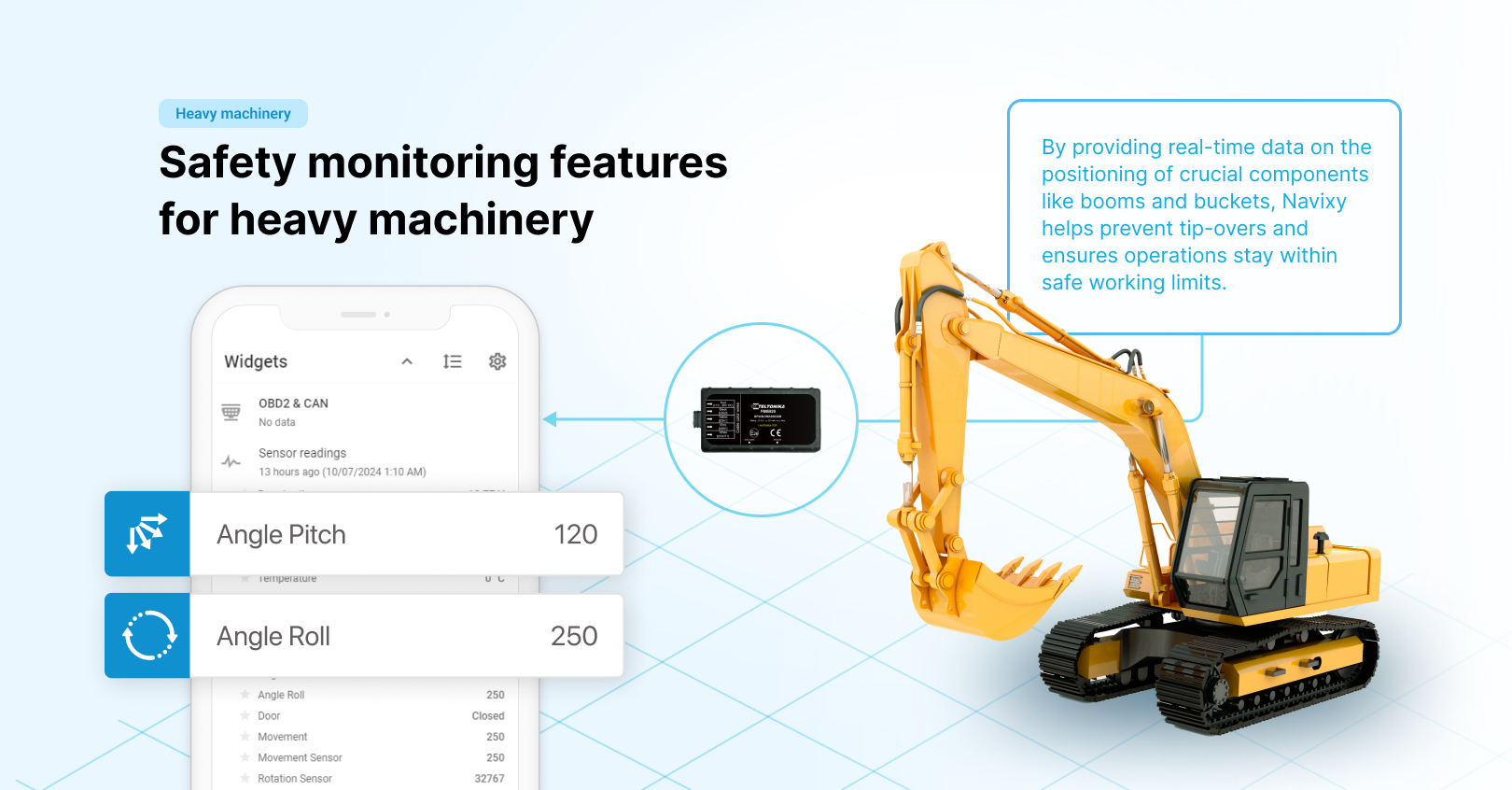

In an industry where safety is paramount, Navixy's position and safety monitoring features serve as a crucial safeguard. The platform's ability to track boom angles and machine tilt is more than a technical feature — it's a life-saving capability. According to the Bureau of Labor Statistics, over 20% of construction fatalities involve heavy machinery (BLS, 2019). By providing real-time data on the positioning of crucial components like booms and buckets, Navixy helps prevent tip-overs and ensures operations stay within safe working limits.

Moreover, the tracking of movement and rotation, such as the rotation sensor readings on a Liebherr machine, offers insights into how equipment is being used. This data is invaluable for training operators, optimizing workflows, and ensuring that machinery is used correctly and efficiently.

Clean power for industrial titans

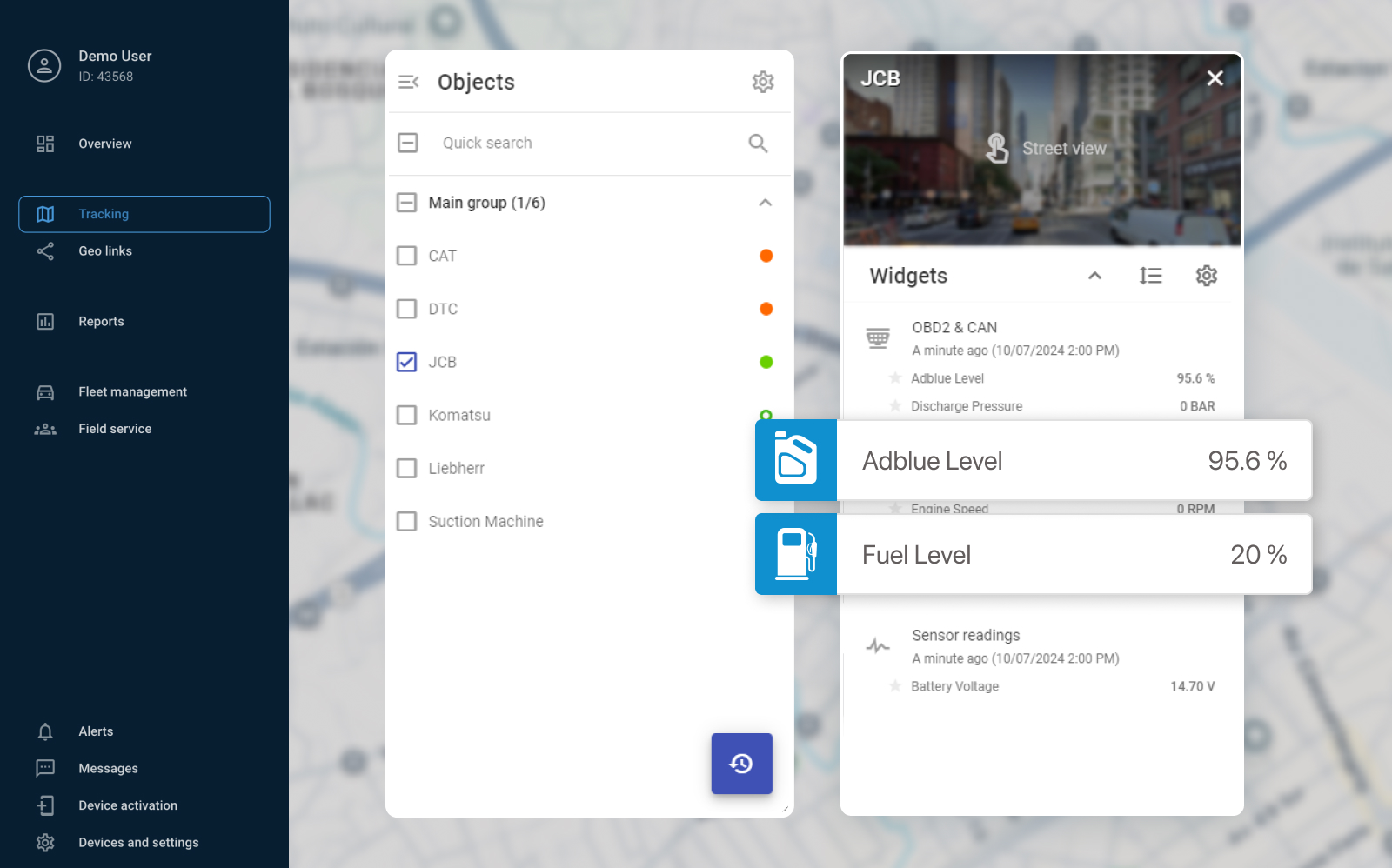

In an era of rising fuel costs and stringent environmental regulations, Navixy's fuel and emissions management capabilities are more crucial than ever. The ability to track AdBlue levels ensures that equipment always meets emissions standards without over-purchasing this consumable.

This level of precise monitoring is essential in meeting increasingly strict environmental regulations. For instance, the European Union's Non-Road Mobile Machinery (NRMM) Regulation sets limits on emissions from engines used in construction equipment, agricultural machinery, and other off-road applications. Navixy's detailed tracking helps ensure compliance with such regulations while optimizing fuel consumption.

The broader impact: transforming industries

The implementation of advanced telematics solutions like Navixy is having a transformative effect across industries that rely on heavy machinery. In construction, for example, telematics is addressing the sector's notorious productivity challenges. McKinsey Global Institute reports that construction productivity has grown by only 1% annually over the past two decades, compared to 3.6% for the manufacturing sector (McKinsey Global Institute, 2017). Telematics is helping to close this gap by optimizing equipment utilization, reducing downtime, and improving project planning.

In mining, where equipment efficiency directly impacts the bottom line, telematics is driving significant improvements. A case study by Caterpillar showed that implementing telematics in a large surface mine improved truck utilization by 10%, translating to millions in additional revenue (Caterpillar, 2018).

For agriculture, where timing is critical, telematics is enhancing precision and efficiency. John Deere reports that its telematics solutions have helped farmers reduce idle time by up to 20%, resulting in significant fuel savings and increased productivity (John Deere, 2020).

The next generation of steel and silicon

As we look to the future, the role of telematics in heavy machinery management is set to expand even further. Emerging trends that platforms like Navixy are well-positioned to address include:

- Integration with Building Information Modeling (BIM)

The convergence of telematics data with digital project models promises to revolutionize project management in construction. A report by Dodge Data & Analytics found that 82% of BIM users report positive ROI, with improved project quality and reduced errors and omissions among the top benefits (The Business Value of BIM, 2020). - Autonomous and semi-autonomous operations

As heavy machinery moves towards automation, telematics will play a crucial role in providing the data backbone necessary for safe and efficient operations. The autonomous construction equipment market is expected to grow from $11 billion in 2021 to $35 billion by 2026, at a CAGR of 25.4% (MarketsandMarkets, 2021). - Advanced predictive analytics

Moving beyond preventive maintenance to truly predictive models that optimize machine lifecycles. IBM estimates that predictive maintenance can reduce maintenance costs by up to 50% and eliminate breakdowns by up to 70% (IBM Institute for Business Value, 2017). - Sustainability tracking

With increasing focus on environmental impact, telematics will offer more granular data on emissions and fuel efficiency to support corporate sustainability goals and regulatory compliance. The CDP reports that 215 of the world's largest companies see climate change as a threat to their business operations, underlining the importance of such tracking (CDP Global Climate Change Report, 2019).

As these trends converge, they paint a picture of a future where heavy machinery operations are deeply integrated with broader business processes, driven by real-time data and predictive insights. Platforms like Navixy, with their comprehensive approach to data management and analysis, are poised to play a pivotal role in shaping this future. By providing the tools for agile decision-making, enhancing operational efficiency and safety, and enabling sophisticated analytics, Navixy is setting the pace for the future of heavy machinery management.

Where Big Data meets Big Machinery

The integration of advanced telematics solutions like Navixy into heavy machinery operations represents more than a technological upgrade — it’s a reimagining of how these critical assets are managed and utilized. With real-time insights, predictive capabilities, and a flexible integration framework, telematics empowers industries to achieve new levels of efficiency, safety, and sustainability.

Ready to revolutionize your heavy machinery operations? Schedule a demo with Navixy today to explore how our customizable telematics platform can address your specific challenges. From real-time monitoring to predictive analytics, discover how Navixy can help you maximize efficiency, enhance safety, and drive sustainability in your operations.