Did you know that fleets can lose thousands of dollars every year due to improper tire inflation? The U.S. Department of Energy found that underinflated tires lower gas mileage by about 0.2%, meaning that companies could struggle to stay competitive as transportation costs rise. Therefore, it’s clear that monitoring tire pressure is vital for businesses to survive.

Thanks to the growing implementation and advancement of Tire Pressure Monitoring Systems (TPMS) that alert drivers of pressure issues, it’s easier to keep tires properly inflated. Not to mention, this tech is required by law in the United States, European Union, and other places, so it’s essential to understand what’s at stake.

With Navixy alerts for tire pressure and our array of integrated devices, businesses have plenty of options when it comes to monitoring their fleets and making them more efficient. If you have questions about setup or support, contact us today.

What is TPMS?

The primary function of TPMS is to accurately measure the air pressure levels of all tires. These can be direct sensors that use a waterproof valve to determine the actual pressure or indirect devices that utilize software to measure pressure levels by observing changes to the wheel’s diameter. Either way, the information is sent to the vehicle’s central control unit and lets the operator know if one or more wheels are under or overinflated.

These automated alerts eliminate much of the guesswork and manual effort that used to be required to check tire pressure. Moreover, they help keep drivers and managers more aware of underinflated tires, ensuring that they’re refilled sooner to prevent damage or an accident.

TPMS are so effective at improving safety that various countries and areas have passed laws to regulate and enforce their usage. For instance, in the EU, all M1 vehicles registered after November 1, 2014, need this type of system. Starting July 2022, the law will also require tire pressure monitoring on M2, M3, N1, N2, N3, O3, and O4 class vehicles. Meanwhile, the TREAD Act, initially enacted in 2000 and subsequently revised, regulates TPMS for private and commercial vehicles in the United States.

Why do fleets need TPMS?

Though a measurement like tire pressure might not seem very exciting or important, fleets have a lot to gain by keeping closer track of this value. From ensuring compliance to helping businesses save, there are myriad ways to benefit from this technology.

First, ensuring proper inflation levels prevents tires from wearing out too quickly. If a tire is chronically over or underinflated, it will likely degrade at a faster rate than one that’s properly maintained. Not to mention, they’re also at a higher risk of a blowout since low tire pressure causes excessive heat to build up in the tire sidewalls. A crash threatens your employees’ safety, damages the company’s reputation, and leads to significant vehicle maintenance costs over time.

Tires that are poorly maintained simply aren’t as reliable as ones that stay properly inflated. And since tire failure causes a significant portion of auto accidents each year, it’s essential to keep your employees and assets safe. The correct pressure level keeps the tread better intact for smoother stops and optimal stability.

Optimally inflated tires are not only safer and last longer; they’re also better for fuel efficiency. According to the Department of Energy, keeping tires at the recommended pressure can boost fuel economy by up to 3%, which means that fleets large and small could see significant savings. With TPMS, you’ll know as soon as a tire drops below the required pressure level. Meanwhile, studies conducted by FMCSA (Federal Motor Carrier Safety Association) have demonstrated that underinflated tires can cost fleets an extra $2,200 per vehicle each year in fuel and maintenance.

Finally, an often overlooked benefit of TPMS alerts is reducing vehicle downtime. Improper tire pressure levels not only impact safety and efficiency, but also other vehicular components, such as the shocks, struts, bearings, and the wheels themselves. Over time, these parts will require more service and more frequent replacements, leading to increased maintenance costs in the long run. Moreover, your fleet will experience more downtime, rendering it less available at crucial times.

- Improved fuel economy

- Better road safety

- Decreased vehicle maintenance costs

- Lessened chance of tire blowout

- Compliance with government regulations

Improve efficiency with Navixy tire pressure alerts

Using TPMS with Navixy’s modern telematics gateway can open several possibilities, including identifying key fleet trends and catching potential problems sooner. To learn more about our tire pressure monitoring solutions or find setup instructions, be sure to visit our Marketplace.

By taking advantage of our alerts and reports, businesses can save both time and money by knowing which vehicles need attention when.

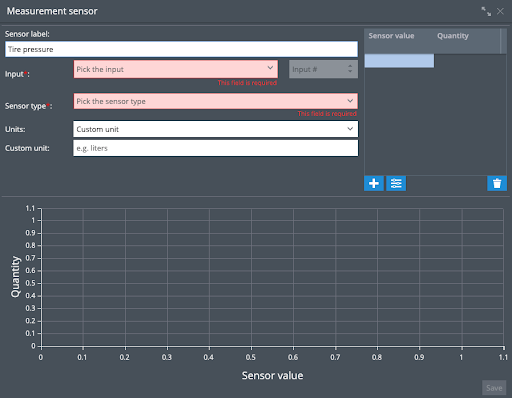

Tire pressure data is typically transmitted over CAN bus or BLE sensors. Devices that support this type of sensor can report such information to the monitoring system. Accordingly, pressure levels will appear in the corresponding widget to assist with keeping fleet operators informed. For additional details, check out the steps for installing a measurement sensor in our User Guides.

Once installed, managers can check the real-time tire pressure, run reports on historic pressure levels for both select vehicles and the whole fleet, and even be informed when the levels drop unexpectedly, which could indicate a blowout. Along with this, historical data, such as which vehicles receive the most tire pressure alerts or if a specific tire needs air more frequently, is available with our Reports. And for quick access to a truck, trailer, or van’s current tire pressure level, simply select the Object and view the Sensor readings widget.

Navixy’s tire pressure monitoring solutions can assist with keeping fleets safe, efficient, responsive, and compliant. Learn more about our mobile resource management platform by contacting a team member today.